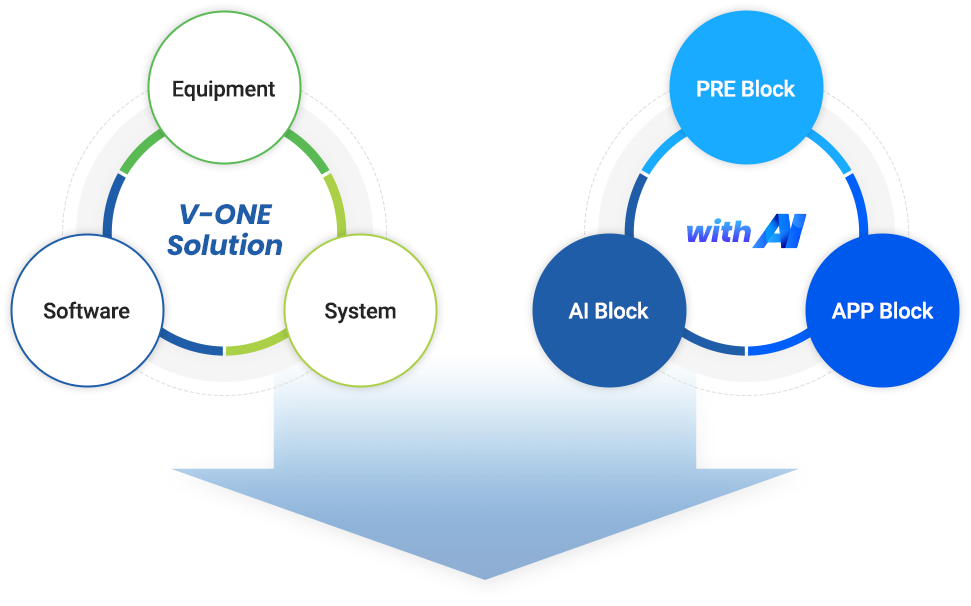

V-ONE’s Solution

-

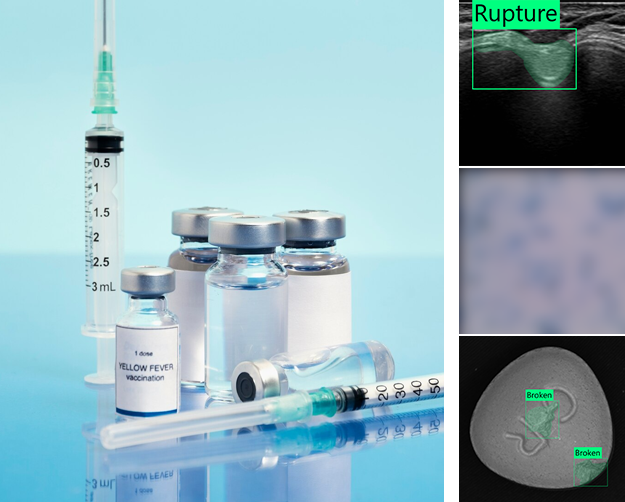

Medical & Pharmaceutical

- Ultrasonic imaging diagnosis

- Reagent classification

- Culture cell inspection

- Syringe inspection

- Fluid foreign body inspection

- Pill surface inspection

-

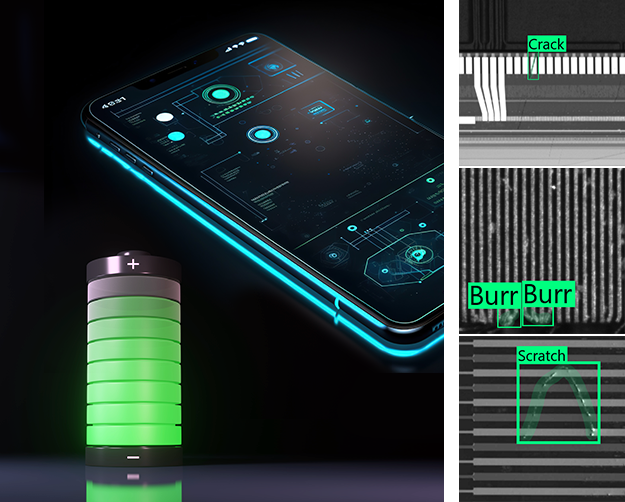

Display & Secondary Battery

- Indentation foreign body inspection

- Inspection of foreign substances, cracks and burrs

- Scratch inspection

- Cell phone surface inspection

- Lead defect inspection

- Stain inspection

-

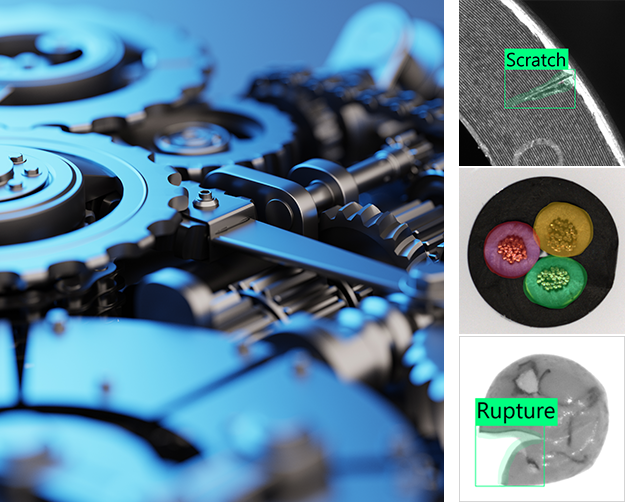

Spare Parts & Material

- Metal bobbin surface inspection

- Liquid capsule contents inspection

- Rubber material surface inspection

- Wire classification/defect inspection

- Lead application inspection

- Wafer crack inspection

-

Logistics & Distribution

- Box/Packaging classification

- Assemble parts classification

- Monitoring for loss of items

- Agricultural goods automatic classification

- Consumer orders inspection

- Packaging/Container OCR reading

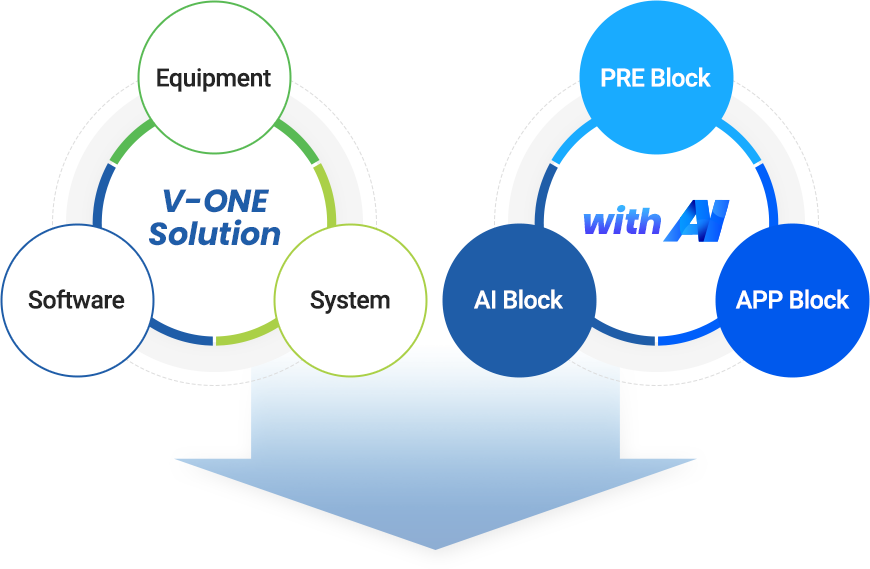

withAI

Quickly develop solutions by using various models based on the V-ONE Solution*, and work easily, clearly through a user-friendly interface.

-

PRE Block

Pre-processing algorithm to improve detection power of inspection images

-

AI Block

API for learning and inference (inspection)

-

APP Block

API for AI project

V-ONE M/V solution has been recognized for its technological prowess and quality excellence in successfully carrying out various machine vision projects such as displays and secondary batteries.

Feature

-

V-ONE solution has a scalability and flexibility respond to various business needs.

-

Provides the ability to inspect various models in one task as needed.

-

Items that could not be inspected using existing inspection equipment can be detected.

-

Rapid inspection possible by supporting self-developed high-speed processing technology and multi-parallel processing technology.

-

Supports an optimization module for inspecting large amounts of image data.

-

Based on the block structure, users can only use the blocks they want.

-

Detection power is improved by suggesting specialized models depending on the inspection target.

-

Supports models that can be used in various fields such as manufacturing, medical care, materials, parts, distribution, and logistics.

Constitution

-

-

Customer

request -

Data collect & processing

-

-

PRE Block

- Customer data processing

- studying by Processed image

- rule base pre processing algorithm for increase inspection power

-

AI Block

Object

DetectionSegmentation

Classification

Anomaly

- Easy and intuitive work with labeling tools provided

- Detection class definition

- Start learning immediately after checking labeling

- Continuous model advancement

- Multi-learning support (Multi GPU) model creation

- Optimization model transformation

- Model validation

- Model quality check by appropriate inspector

-

-

APP Block

-

V-ONE

Solution

- Inspection model provided

- API support for AI projects

- Supports S/W customization in the way the customer needs

- Support method (project, module, consulting)

- Equipment development*

- Optical module + model + API*

- Model + API*

-

-

-

Support model & Consulting, Project

-

Customer

-

-

Equipment*

-

- AOI

- AMI

- DMS

- Etc.

-

-

withAI

-

-

Part’s (Module)*

-

- Optic

- V-one Solution

- withAI

-

- Display

- Secondary battery

- Medical

- Material

-

-

Application*

-

withAI

-

API

-

Detail View

withAI

PRE BlockPreprocess

- Auto-Labeling

- Auto-Tuning

- GAN (Generative Adversarial Networks)

- Algorithm for improving video quality

- Algorithm which is adjust shape for suitable image of model

- Algorithm of simplifying model to improve model accuracy

- Algorithm for classification

- Algorithm of converting frequency for speckle inspection

- Algorithm of feature extraction from image

- Algorithm of finding shape in image information

- Neural network (MLP)

- Customizing Module

withAI

APP BlockApplication

- Provide public Lib for AI model inspection

- ONNX model provided

- Optimized engine providing for inspection time reducing

- C/S App through learning and inspection server operation provided

- Mobile model provided

- Provides for apps tailored to customer needs

- Industry-specific business models provided

- Customizing Module

withAI

AI BlockObject Detection

- After classifying the object and detecting its location If it is determined to be an object, it is displayed as a rectangle

- Detect multiple objects in one image

- Using pre- trained model, improve detection accuracy and time reduction

- Select an appropriate model according to the process and task pre-learning and inspection

Medical / Pharmaceutical

- Model dedicated to pill surface inspection provided

- Model dedicated to the inspection of foreign substances in injected fluid. Provided

- Model dedicated to specimen bin classification provided

Materials

- Model dedicated to metallic appearance inspection provided

- Model dedicated to surface inspection of rubber materials provided

- Model dedicated to electronic component/board inspection provided

- Model dedicated to wafer surface inspection provided

Logistics

- Model dedicated to product classification provided

- Model dedicated to classification of agricultural products provided

- OCR reading model provided

Display

- Model dedicated to edge crack inspection provided

- model dedicated to lead burr inspection is provided

- Model exclusively for mobile phone surface inspection is provided

Segmentation

- Classify objects by dividing into pixels, display location

- Detect multiple objects in one image

- Using pre- trained model, improve detection accuracy and time reduction

- Select an appropriate model according to the process and task pre-learning and inspection

Med / Pharmaceutical

- Ultrasound imaging diagnostic model provided

- Cultured cell inspection & classification models provided

Materials

- Model dedicated to wafer surface inspection provided

Display

- Speckle inspection model provided

- inspection models for cracks, foreign substances, contamination provided

Classification

- Determine object type and classified

- Determine one object in one image

- Using pre- trained model, improve detection accuracy and time reduction

- Expected improvement in output when fused with Pre-Block

- Select an appropriate model according to the process and task pre-learning and inspection

Med / Pharmaceutical

- Drug classification model provided

Logistics

- Pre-Block combination, OCR reading model provided

Anomaly

- Judgment into normal and abnormal binary types

- Judged as normal/bad in one video

- Learning time is fast as it learns only from normal images

- Collecting poor training data Improves training time and detection accuracy by using pre-trained models

Parts/Materials

- Provides a model for inspecting the presence or absence of lead coating on the board

Logistics/Distribution

- Box damage inspection model provided

Applying Field

-

Medical & Pharmaceutical

-

Ultrasonic imaging diagnosis

-

Culture cell test - Live, Dead, Debris classification

-

Medicinal type/grade classification

-

Foreign substances in injected fluid, print inspection.

-

Classification by specimen container type

-

Pill breaks, scratches, color, and shape inspection

-

-

Material & Parts

-

Inspection of metal bobbins for nicks and scratches

-

Inspection of inner cable color for wire cross sections

-

Inspection of capsule contents for bubbles and bursting

-

Inspection of wafer scratch and speckle

-

Inspection of lead soldering application (none lead, over lead, less lead, short)

-

Inspection of rubber ring colored foreign matter, tear, and edge

-

-

Display & Secondary battery (Rechargeable)

-

Inspection for Edge crack & damage

-

Lead burr, open, short defect inspection

-

Speckle (dot, line, north pole) inspection

-

Mobile phone scratches, camera and fingerprint sensor scratches, and surface inspection for cracks

-

-

Logistics & Distribution

-

Sorting boxes on the move

-

sorting screws which for assembly of finished products

-

Automatic classification of agricultural products by size

-

Inspection of customer order item & ship and return product

-

OCR reading of packaging, containers, etc.

-

-

Foods & Packaging

-

Inspection of cosmetic containers for breaks, scratches, and foreign substances

-

Inspection of expiration date printing on packaging

-

Inspection of Can, bottle, canned food printing and damage

-

Inspection of contamination and foreign substances in food

-

-

Robotics Autonomous Driving

-

AMR (Autonomous Mobile Robots)

-

Location measurement and real time map generation

-

Path creation, avoiding object, collision prevention through Object detection technology

-

Prediction of drivable area using Segmentation

-

Reinforcement Deep learning-based multi robot and avoid obstacle, abnormal detection

-

Real time collaborative detection with camera detection and DDS combined sensors

-

Product List

withAILite |

withAIProfessional |

withAIMedical |

|||

|---|---|---|---|---|---|

| Object-Detection | |||||

| Instance Segmentation | |||||

| Classification | |||||

| Anomaly | |||||

| Semantics Segmentation | |||||

| Learning Model | Small | Large | Large | ||

| Multi GPU | 1 | 2 | 2 | ||

| ONNX | |||||

| Optimized Inference | |||||

| Multi Threading | |||||

| Auto Learning | |||||

| Customizing | |||||

|

Logistics / Distribution |

Industrial |

Medical / Pharmaceutical |

Specification

withAI Lite

withAI Professional

| division | Minimum specifications | Recommended specifications | |

|---|---|---|---|

| Train PC | CPU | Intel i7 or more | Intel i7 or more |

| RAM | 16GB | 32GB | |

| CUDA Compute Capability | 3.5 | 3.5 | |

| GPU | Geforce RTX 4070 (12GB or more) | Geforce RTX 4090 (24GB or more) | |

| OS | Windows 10 x64, Windows 11 x64 | ||

| Inference PC | CPU | Intel i7 or more | Intel i7 or more |

| RAM | 16GB or more | 32GB or more | |

| GPU | Geforce RTX 4070 (12GB or more) | Geforce RTX 4080 (16GB or more) | |

| OS | Windows 10 x64, Windows 11 x64 | ||

| Develop environment | Visual Studio 2017 or more | ||

withAI Medical

| division | Minimum specifications | Recommended specifications | |

|---|---|---|---|

| Train PC | CPU | Intel i7 or more | |

| RAM | 32GB | ||

| CUDA Compute Capability | 3.5 | ||

| GPU | GeForce RTX 4090 (24GB or more) | ||

| OS | Windows 10 x64, Windows 11 x64 | ||

| Inference PC | CPU | Intel i7 or more | Intel i7 or more |

| RAM | 16GB or more | 32GB or more | |

| GPU | Geforce RTX 4070 (12GB or more) | Geforce RTX 4080 (16GB or more) | |

| OS | Windows 10 x64, Windows 11 x64 | ||

| Develop environment | Visual Studio 2017 or more | ||