컨텐츠 영역

Display Inspection System

AKKON AOI System

-

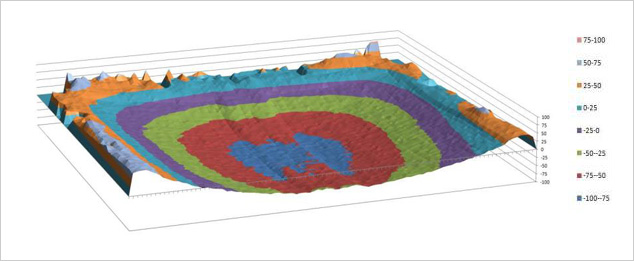

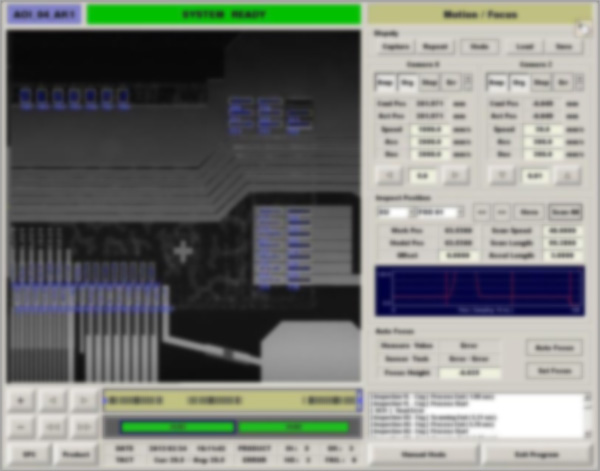

The machine is equipped with the vision system, which identifies automatically using a differential interference contrast optical microscope whether the auto-bonding process is OK or NG by measuring the number, the strength, the length and the distribution of conductive particles residing in the leads.

- Optimized DIC Microscope

- Auto Focus (by Laser Displacement Sensor)

- Many Type of Scan Speed, FOV, Resolution

- COG align ± 1μm with IR Inspection

※ The blurred images are intentionally processed due to IP protection. Please contact us for the detail information.

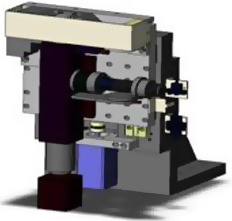

COG /FOG Bonding Alignment System

Align LCD Panel and IC/FPC. Inspect the status of alignment before bonding the COG/FOG

※ The blurred images are intentionally processed due to IP protection. Please contact us for the detail information.

TAB Bonding Alignment System

Align LCD Panel and TAB. Inspect the status of alignment

※ The blurred images are intentionally processed due to IP protection. Please contact us for the detail information.

3D POL FPR Aligment & Inspection System

The system aligns 3D FPR film on display panel and inspect alignment of FPR and Panel by using vision system.

※ The blurred images are intentionally processed due to IP protection. Please contact us for the detail information.

After POL AOI System

It is equipped with the vision system, which automatically inspect Particle / Scratch / Edge broken on both sides of Panel after POL attaching process by using a line scan technology.

※ The blurred images are intentionally processed due to IP protection. Please contact us for the detail information.

Before & After Cleaner AOI System

It is equipped with the vision system, which automatically inspect Particle / Scratch / Edge broken on both sides of glass before/after cleaning process by using a line scan technology.

Before Cleaner

After Cleaner

※ The blurred images are intentionally processed due to IP protection. Please contact us for the detail information.

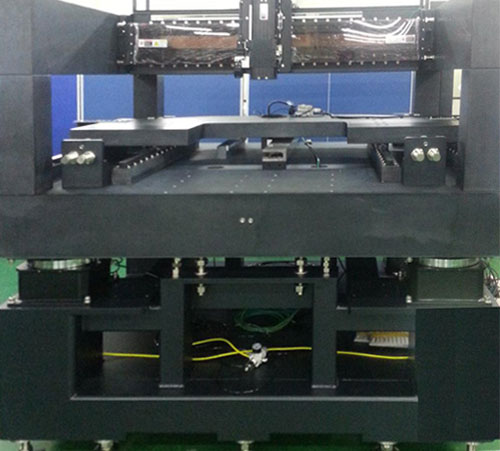

AKKON AOI M/C

It is all-in-one AOI M/C with AKKON AOI System and optimized mechanical design.

OLED Fine Metal Mask AOI M/C

This M/C inspects PPA (Pixel Position Accuracy), Mask hole size, Critical dimension, bias for Mask and assignment Mask Frame.